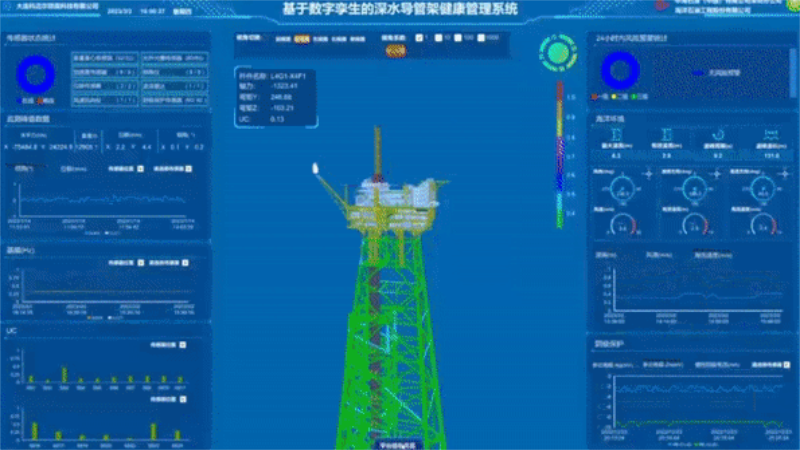

数字孪生管理系统是基于亚洲首个300米深水导管架“海基一号”建造的。通过智能传感和数字孪生技术的集成,该系统连接了一个虚拟和一个真实的两个强大平台,这两个平台协同工作,实现了水下结构的全面数据捕获、安全管理的远程控制和智能风险预警能力。该系统是中国海上油气数字化转型的典范,突显了中国在技术创新方面取得的巨大进步。经过40周的稳定测试运行,该系统收集了大量数据,数据量几乎达到2TB。在此期间,该系统经受了多个台风的考验,并成功地从“Ma on”、“NESAT”和“Nalgae”三个特定台风中获得了宝贵的数据,进一步巩固了其作为一个强大可靠系统的声誉。

本项目开发的导管架数字孪生软件系统融合了综合数据管理、监测、预警、检测、评估和数字孪生等多种功能。这一尖端系统能够实时监控和显示平台数据。通过不断积累监测数据和迭代更新数据库,系统对导管架进行实时分析和智能数据采集。在真实导管架和常规评估计算的支持下,该平台建立了一种可靠的方法来评估局部风险状态。

此外,该管理系统实现了在线操作和维护管理,为优化深水导管架的未来设计和规格铺平了道路。

Recently, COOEC has taken a crucial step forward in the field of deep-water digital twins with the formal operation of the world’s first digital twin management platform of deep-water jacket. The significance of this self-developed platform also lies in its ability to enhance the intelligent risk early-warning and life-cycle operation and maintenance management of deep-sea oil and gas equipment.

The digital twin management system is built based on the 300-meter deep-water jacket "Haiji-1" ,which is the first of its kind in Asia. Through the integration of intelligent sensing and digital twin technology, the system connects two powerful platforms ,one virtual and one real ,that work in unison to enable comprehensive data capture of underwater structures, remote control of safety management, and intelligent risk-warning capabilities. The system serves as an exemplar for China's offshore oil and gas digital transformation, highlighting the country's impressive strides in technological innovation. After 40 weeks of stable test operation, the system has collected an impressive volume of data amounting to almost 2TB. The system has endured many typhoons during this period and has successfully obtained valuable data from three specific typhoons, namely "Ma-on", "NESAT", and "Nalgae", further cementing its reputation as a robust and reliable system.

The jacket digital twin software system developed in this project incorporates multiple functions, such as integrated data management, monitoring, early warning, detection, evaluation, and digital twin. This cutting-edge system enables real-time monitoring and display of platform data. By continuously accumulating monitoring data and updating the database iteratively, the system performs real-time analysis and intelligent data capture of the jacket. With the support of the real jacket and routine assessment calculations, the platform has established a reliable method to evaluate the local risk status.

Additionally, the management system enables online operation and maintenance management, paving the way for optimizing future design and specification of deep-water jackets.